double facer machine

★Hot Plates’ surfaces is grinded and then chromed plated,width:600mm.total 16pieces of hot plates, cold shaping part:6m length.

★Hot plates are made by container plates, can pass the national first level pressure container standards

★Hot plates adopt the compressed gravity press rollers; structure.

★Press rollers’ lifting up and down is driven by electric structure.

★Up convey belt left and right correct by manual with both sides, tension adjusting system: 2 sets, pneumatic adjust.

★Drive rollers’ surface is wrapped by rubber, Y shape structure with middle height to make sure the board can be out smoothly

★Drive part, gear oil drown lubricating type, with liquid level meter shown.

★Main drive motor: Variable frequency motor, high force when low speed start, high speed adjusting range, steady to use, easy to mend

※Common Spec:

1, working width: 1600mm

2, Operation Direction: Left or right (decided by the workshop of customer)

3, Max machinery speed: 180m/min

4, Temperature requirement: 160—200℃ Steam Pressure: 0.8-1.3Mpa

5, Air pressure:0.6—0.9Mpa

6, Cool shaping length: 6.5m Heating plates amount:20 pieces

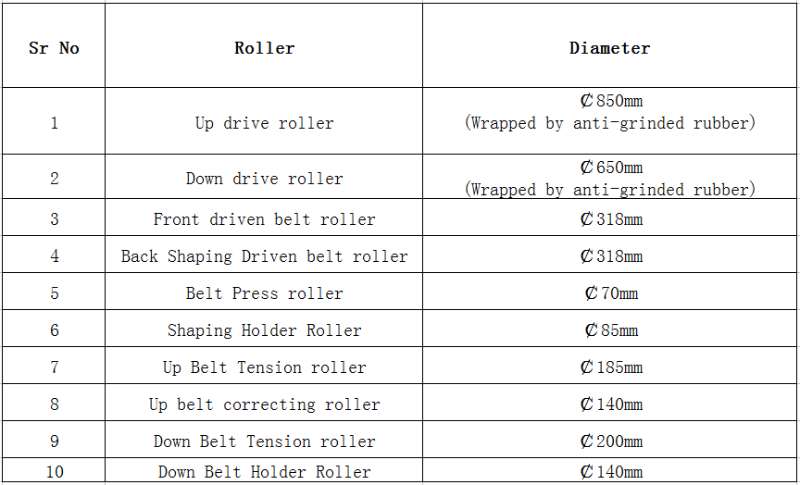

※Spec of the rollers’ diameter:

Note: All the surfaces of the rollers are grinded and then chromed plated.

※Spec of Motor:

Main Drive Motor: 75KW(variable frequency) Voltage: 380V 50Hz Continuous (S1) working Type

Hydraulic station motor: 2.2kw Voltage: 380V 50Hz Continuous (S1) working Type

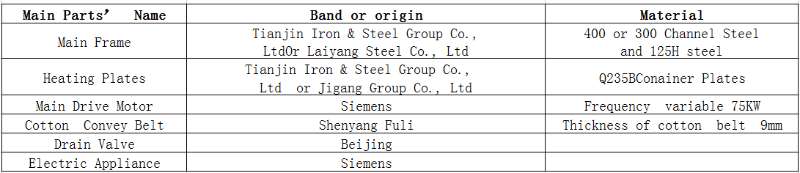

※Spare Parts that need to buy from others and main materials: